Pipe Marker Submittal Data Sheets (orange links)

Brimar Pipe Marking Submittals comply with:

ANSI / ASME A13.1-2015 Scheme for the Identification of Piping Systems and ANSI Z53.1 Safety Color Code for Marking Physical Hazards.

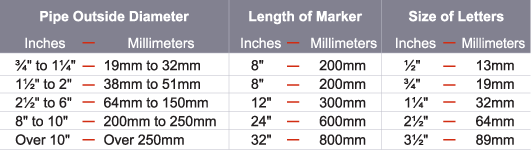

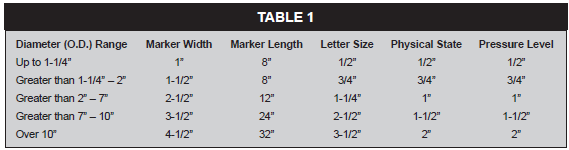

Pipemarker.com meets ANSI & ASME A13.1 2015 Type and Letter Size requirements: Brimar uses sans serif gothic bold lettering (Arial Bold) when manufacturing pipe markers to provide high readability and contrast with marker color.

Pipemarker.com meets ANSI / ASME A13.1 2015 Marker Size requirements: Brimar follows the size recommendations supplied on this standard for all of our pipe marking products.

Pipemarker.com meets ANSI / ASME A13.1 2015 Color requirements: Our color selection matches the color assignment specified in ASME A13.1-2015 Scheme for the Identification of Piping Systems and follows the color requirements in ANSI Z535.1 Safety Color Code.

Pressure Sensitive labels that adhere to pipe insulation by peeling back liner off. The outdoor life expectancy of these markers is rated to be between 4 to 5 years Mid Continental US. Installation requires clean and dry surfaces with a minimum of 50° F application temperature. Markers comply with ANSI / ASME A13.1 2015 Standard when used with directional flow arrows, such as EZ Arrows or Arrow Banding Tape.

Fast and easy installation, is what makes this marker the #1 choice among contractors. Uncoil and release to place marker onto the pipe. No surface preparation or application temperature is required when installing them. This marker complies with ANSI / ASME A13.1 2015 Standard. These are 2 aspects that make these markers unique: 1) Arrows direction, regardless of the position of the marker, the arrows will point in the correct flow direction 2) Markers have a 360° visibility due to the mirror legend format.

Economical alternative to EZ Pipe Markers supplied in roll form. Each roll contains 50 markers plus 50 die cut arrows and are available in 2 different sizes. Small rolls should be used on pipes up to 2-1/4" O.D. and Large rolls should be used on pipes from 2-1/2" to 7-7/8" O.D.

30 ft long easy to handle, lower cost rolls. Available in 2 sizes: Small rolls should be used on pipes up to 2-1/4" O.D. and Large rolls should be used on pipes from 2-1/2" to 7-7/8" O.D. Small rolls contain 240 markers (repeats), Large rolls contain 144 markers (repeats).

System #4 Pipe Markers™ were designed to withstand harsh chemicals, abrasion, and weather all types of environments. The printed legend is laminated between two layers of chemical and high temperature resistant polyester, creating an extremely DURABLE pipe marker.

Color coded self adhesive vinyl markers that include a die cut directional arrow. Brimar advises the application of markers near points where ducts enter into concealed spaces and at maximum intervals of 50 feet in each space where ducts are exposed or concealed by removable ceiling system.

Color classification for duct markers are as follow:

Green for cold-air supply ducts

Yellow for Hot-air supply ducts

Blue for exhaust-, outside-, relief-, return-, and mixed-air ducts.

Duct markers are avaialble in 3 different formats,

Stock Labels (2 sizes: 16 x 2-1/4" & 24 x 4"),

Stock Rolls (16 x 2-1/4") and

Multiline Duct Markers (2 sizes: 16 x 4-1/2" & 7-1/2 x 4-1/2"), all formats are provided with arrows

Brimar Medical Gas Submittals are in compliance with:

NFPA 99 2015 Health Care Facilities Code

CGA C-9 Standard Color Marking of Compressed Gas Containers for Medical Use.

All medical gas piping, valves and manifolds should have permanent labels bearing the name or chemical symbol of the gas/vacuum system they carry or control. Also where positive pressure gas pipe systems operate, the label should include the operating pressure in addition to the name of the gas/vacuum system. Brimar medical gas markers are color coded as per NFPA 99 2015 Table 5.1.11.

Medical Gas Markers should be located as follows:

- At intervals of not more than 20 feet / 6.1 m apart

- At least once in or above every room

- On both sides of walls or partitions penetrated by the piping.

- At least once in every story height traversed by risers.

Brimar manufacturers a complete line of medical gas pipe markers. These markers conform to the NFPA 99 2015 Standard and the CGA C-9 Color Standards. Brimar's medical gas markers are manufactured with the best vinyl, ink and adhesives available to ensure long life. They are also available in a wide range of colors and are designed to wrap completely around 3/8" to 2" piping.

Brimar Ammonia Marker Submittals are in compliance with:

IIAR Bulletin #114 2014 Identification of Ammonia Refrigeration Piping & System Components

Brimar's compliance with above standard is complete. We meet all the requirements stated on said standard such as:

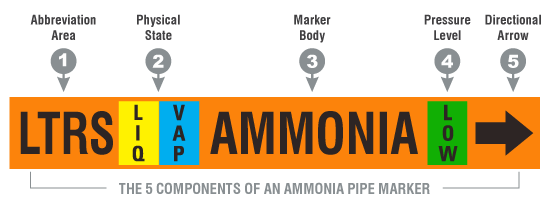

Ammonia pipe markers will contain or be divided in 5 section or components:

- Abbreviation Section: Printed in black

- Physical State Section: Either LIQUID or VAPOR

Printed in yellow for Liquid and sky blue for Vapor - Marker Body: Body color to be Safety Orange and contain the refrigerant "AMMONIA" printed in black

- Pressure Level Section: Either LOW or HIGH.

Pressure in excess of 70 psig will be considered to be high pressure and printed in black letters on a red band.

Pressure equal to or less than 70 psig will be considered to be low pressure and printed in black on a green band. - Directional Arrow: Detachable arrow printed in black

These markers were developed to help contractors comply with ANSI / ASME A13.1 standards for piping identification and IIAR's Recommended Guidelines, Bulletin #114. Each marker is printed with the appropriate abbreviation, the corresponding physical state & pressure rating, and the necessary directional flow arrow. This allows the installer to mark each location with one quick and easy step.

- Each marker is supplied with a die cut arrow that can be applied in any direction

- Self adhesive fade resistant vinyl

Ammonia pipe markers were designed to identify the refrigerant (i.e., ammonia), the physical state of the refrigerant, the relative pressure level of the refrigerant and the direction of flow. Ammonia markers should be located as follows:

- Before and after a change in piping direction; when piping terminates at equipment and is within 24" of a marker or when piping changes direction more than once and is within 24" of a marker, it is not necessary to place an additional marker between the directional changing elbows or the termination point at equipment.

- Before and after piping penetrations of walls, ceilings and floors,

- On extended horizontal or vertical runs of pipe, with a maximum spacing of 40 feet between markers, in order to provide positive identification, and

- At least once on the piping in every area through which the refrigeration piping passes.