ANSI/ASME A13.1 2015 Scheme for the Identification of Piping Systems

Latest Revision ANSI / ASME A13.1 2015:

Primary Means of Identification:

The legend (name of the pipe content) and directional flow arrow remain the primary means of identifying pipe content. The size and placement of the marker and arrow has not changed. See ANSI/ ASME Size Chart below and installation guide for details.

ASME A13.2015 3.1 Legend: "Positive identification of the contents of a piping system shall be by lettered legend, giving the name of the contents in full or abbreviated form. Arrows shall be used to indicate direction of flow. Where flow can be in both directions, arrows in both directions shall be displayed. Contents shall be identified by a legend with sufficient additional details such as temperature, pressure, etc. as are necessary to identify the hazard."

Pipemarker.com meets ANSI & ASME A13.1 2015 Type and Letter Size requirements: Brimar uses sans serif gothic bold lettering (Arial Bold) when manufacturing pipe markers to provide high readability and contrast with marker color.

Additional Means of Identification ASME A13.1 2015

ASME A13.1 has incorporated the GHS pictograms into the new 2015 revision and has recommended their use as part of the legend.

"The applicable GHS pictogram as illustrated in Fig. 1 may be included as part of the legend. Where piping is connected to containers that are labeled in accordance with GHS requirements, a corresponding label on the piping may be provided. The corresponding label should contain at least the product name or identifier, the pictogram, the signal word, and the physical, health and environmental hazard statements."

Secondary Means of Identification:

The secondary means of identification is the color code of the marker. The exact colors are contained in the ANSI Z535.1 Safety Color Code.

ASME A13.2015 3.2 Color: "Color should be used to identify the characteristic hazards of the contents. Color should be displayed on, or contiguous to, the piping by any physical means, but its use shall be in combination with the legend..."

Brimar Products Compliance:

The new standard does not require the replacement of previously installed markers. The standard only applies to new installations. Brimar products comply with ANSI / ASME A13.1 standards and we are committed to a uniform standard of pipe identification. However, we recognize that it's not possible or realistic for everyone to adopt the new 2015 standard immediately and therefore Brimar will continue to offer markers that comply with the old and new standards. For our product offering Brimar has identified which color combinations comply with which standard, either the 1996 or the 2015 version.

ANSI / ASME A13.1 Designation of Colors

| FLUID SERVICE | COLOR COMBINATIONS |

| Fire Quenching Fluids

This classification includes water, foam and CO2 used in sprinkler systems and fire fighting piping systems. |

|

| Toxic & Corrosive Fluids

This classification includes fluids that are corrosive or toxic, or will produce corrosive or toxic substances when released. |

|

| Flammable & *Oxidizing Fluids

Flammable: This classification includes fluids, which, under ambient or expected operating conditions, are a vapor or produce vapors that can be ignited and continue to burn in air. |

|

| Combustible Fluids

This classification includes fluids that can burn, but are not flammable. |

|

| Potable, Cooling, Boiler feed, & other Water | |

| Compressed Air | |

| Defined by the User | |

| Defined by the User | |

| Defined by the User | |

| Defined by the User | |

| * New 2015 classification, Oxidizing Fluids | |

Pipemarker.com meets ANSI & ASME A13.1 2015 Marker Size requirements:

Brimar follows the size recommendations supplied on this standard for all of our pipe marking products.

ANSI / ASME A13.1 2015 Size Chart (Pipe Overall Diameter, Marker Size & Letter Height)

The following chart shows the recommended pipe marker letter height and marker size based on the outside pipe diameter of the pipe to be identified. For pipes O.D. smaller than 3/4" (19mm) and for valve and fitting identification, the use of a permanent legible tag is recommended.

For pipes with O.D. of 3/4" to 1-1/4" (19 to 32mm) Legend Size: 1/2" (13mm) high Marker Size: 8" (200mm) wide |

For pipes with O.D. of 1-1/2" to 2-3/8" (38 to 60mm) Legend Size: 3/4" (19mm) high Marker Size: 8" (200mm) wide |

For pipes with O.D. of 2-1/2" to 7-7/8" (64 to 150mm) Legend Size: 1-1/4" (32mm) high Marker Size: 12 (300mm) wide |

For pipes with O.D. of 8" to 10" (200 to 250mm) Legend Size: 2-1/2" (64mm) high Marker Size: 24" (600mm) wide |

For pipes with O.D. over 10" (250mm) Legend Size: 3-1/2" (89mm) high Marker Size: 32" (800mm) wide |

|

Installation Recommendations:

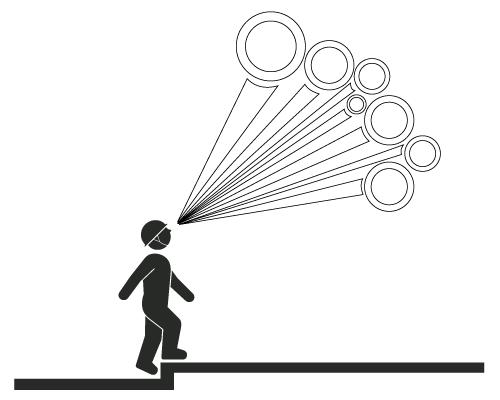

Always position pipe labels on pipes to achieve the best visibility.

Install pipe labels below or above the horizontal centerline of the pipe when pipes are located above or below the normal line of vision. |

|

Install pipe labels close to valves or flanges

|

Install pipe labels near branches and whenever a pipe changes direction.

|

Install pipe labels before and after all wall, floor and ceiling penetrations

|

Install pipe labels at frequent intervals on straight pipe runs.

Brimar recommends 25 ft. |

The above information is our interpretation of the standard and related changes. To obtain a copy of the latest ANSI / ASME A13.1-2015 visit www.asme.org