Go Back to Fire Sprinkler System Signs

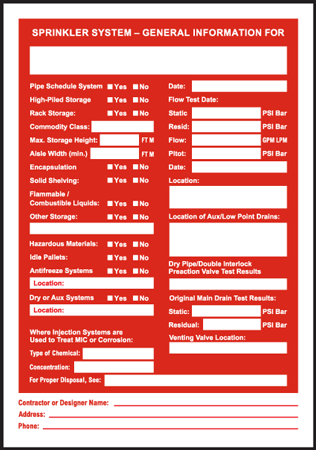

- Hydraulic Systems Sprinkler Sign in compliance with NFPA 13 2018 - 25.6 General Information Sign

- Manufactured with Rust Free .020 White Aluminum provided with four mounting holes at 0.218" dia.

- Outdoor Durability: 4 to 5 years / Service Temp Range: -40° F to 212° F / Printed with UV Resistant Inks.

Sprinkler System General Info SignFire Sprinkler System Signs

Quantity Pricing

| Sign / Plate Size | Item Description / Material | Item Number | 1+ | 10+ | 25+ |

|---|---|---|---|---|---|

| 7 x 10" | .020 White Aluminum | SPR-19-FA | $9.00 | $7.95 | $7.00 |

NFPA 13 – 25.6 General Information Sign

25.6.1 The installing contractor shall provide a general information sign used to determine system design basis and information relevant to the inspection, testing, and maintenance requirements required by NFPA 25.

25.6.1.1 Such general information shall be provided with a permanently marked weatherproof metal or rigid plastic sign, secured with corrosion-resistant wire, chain, or other acceptable means.

25.6.1.2 Such signs shall be placed at each system control riser, antifreeze loop, and auxiliary system control valve.

25.6.2 The sign shall include the following information:

- Name and location of the facility protected.

- Occupancy classification.

- Commodity classification.

- Presence of high-piled and/or rack storage.

- Maximum height of storage planned.

- Aisle width planned.

- Encapsulation of pallet loads.

- Presence of solid shelving.

- Flow test data.

- Presence of flammable/combustible liquids.

- Presence of hazardous materials.

- Presence of other special storage.

- Location of venting valve.

- Location of auxiliary drains and low point drains on dry pipe and preaction systems.

- Original results of main drain flow test.

- Original results of dry pipe and double interlock preaction valve test.

- Name of installing contractor or designer.

- Indication of presence and location of antifreeze or other auxiliary systems.

- Where injection systems are installed to treat MIC or corrosion, the type of chemical, concentration of the chemical, and where information can be found as to the proper disposal of the chemical.